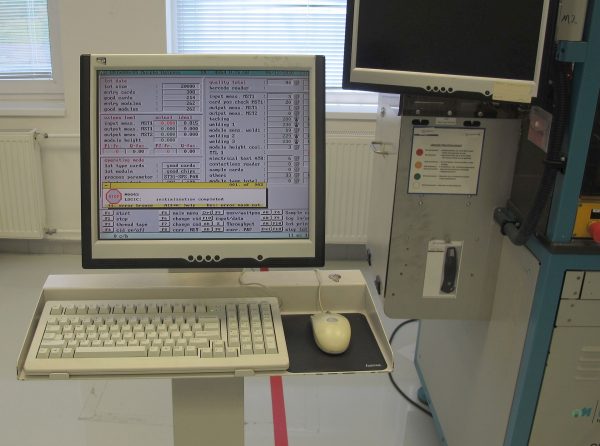

Description

Functional units

- Input transport with magazine changer

- Card input measurement and recognition of card position

- Verification of card thickness (measuring point within module / ISO position). Optical enquiry of printed position marks

- Milling station Independently programmable axes (x,y,z). Milling accuracy ± 30 μm in x and y and ± 15 μm in z

- Cleaning station Rotating blast air and vacuum cleans the cavity from milling dust or cuttings

- Output measurement Measuring of the actual cavity depth. Measuring accuracy: ± 2,5 μm. Online readjustment of milling head on the basis of measuring results

- Module implantation with tacking Module punch. Pick and place unit

- Welding station 3 stations

- Cooling station 1 station

- Optical inspection Module place position in X/Y direction and module surface

- EM 3325 LAM Module tape and adhesive tape unwinder. Laminating press. Hole punch. Rewinder for carrier adhesive tape

- Module transport Transport system for module and spacer tape

- Electrical station ATR verification

- Output transport with magazine changer